Fixation Technology→High Washing Endurance

extile Processing Technology

In textile processing application, it is generally thought that adding Photocatalyst materials in the middle of spinning will result in fabrics with Photocatalyst functions. However, it is an improper method since the mixture is uncontrollable and most importantly, Photocatalyst may decompose fabrics and be covered by dyes or other additives afterward. As mentioned above, Photocatalyst will only work while attaching on the outermost surface of objects for light exposure. Even if Photocatalyst is still effective accidentally by this method, fibers will be easily decomposed and aged by Photocatalyst since they are organic matters, or the dye on fabrics might be broken down and faded as well. And it is even more unfeasible while applying on natural fibers.

Therefore, Photocatalyst must be fixed onto fabrics via post-processing either on finished cloth or on finished garments. There are several main challenges of Photocatalyst processing on textile including acquiring specialized facilities, evenly diffusing materials on fibers, and fixing them onto fabrics with strong washing endurance. It is required to utilize particular equipments and follow standardized and complicated processing protocols inspected by experienced technicians to attain the optimal performance on ARC-FLASH Photocatalyst-processed fabrics.

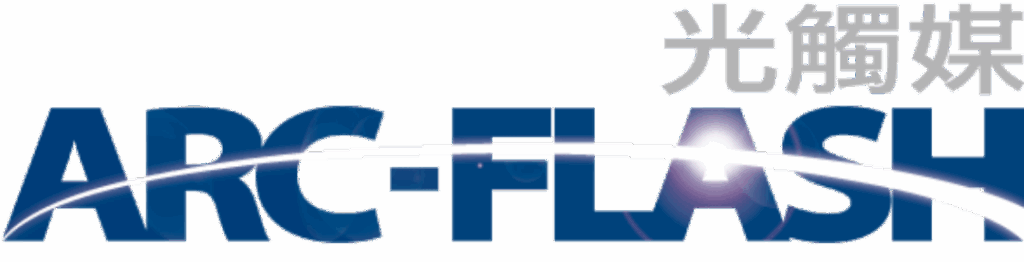

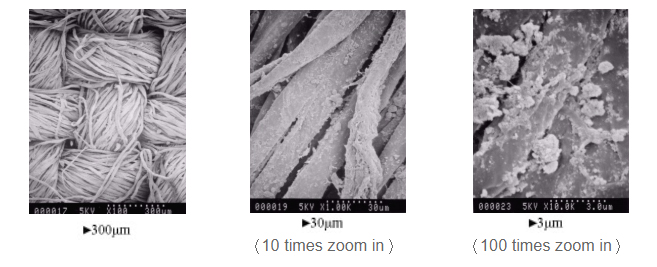

Appearance of ARC-FLASH Photocatalyst-processed fibers under Electron Microscope

It is shown clearly from the section that ARC-FLASH Photocatalyst coheres on the surface of fibers very evenly, and form a dense Photocatalyst layer. Only an excellent Photocatalyst processing technology can make Photocatalyst penetrate through the fibers and achieve the effects of Antimicrobial, Deodorizing, Anti-molding, Self-Cleaning, UV-light Blocking, and Anti-static.

High Washing Endurance

Generally speaking, there is a weakness of instability on functional textile with post-processing treatments. For example, ordinary post-processing treatments of anti-bacteria on fabrics can not stand machine wash for more than 10 times, and effects of some deodorizing products will be lost after water wash due to short of compactness. Others with moisture-absorbing functions can not be soaked in detergents and softeners or else the effects will disappear by chemical reactions.

ARC-FLASH Photocatalyst-processed textile can endure a repetitive machine wash of 150 times and still maintain Photocatalyst adhesion as well as the anti-bacterial rate of 99.9% based on the reports of Japanese Ministry of Health and Wealth. It is also the only product approved by Taiwan Textile Federation’s standard for medical use with a 99.9% anti-bacterial rate after 50 times of machine wash. Besides, it will never lose the performance by being soaked in detergents or softeners owning to state-of-the-art technology and achieve advantages of long-term effectiveness, stability, diverse functions and powerful effects.

http://www.arc-flash.com.tw/pop2-1-5b.htm