TiO2 Concentration / Dispersion / Binders

TiO2 Concentration

The quality of Photocatalyst (i.e. product efficiency) is mostly determined by the TiO2 level in materials; which means, the more TiO2 it contains, the better quality and efficiency it will have. The TiO2 concentration in ARC-FLASH

Photocatalyst materials reaches 30% and it obviously has an edge over other Photocatalysts with a TiO2 level less than 1%. TiO2 is white and of solid state, so TiO2 concentration in material can be judged from its appearance. When the TiO2 level is low, the material is transparent and watery; however, it will become white once TiO2 is over 10%. The more TiO2 it contains, the thicker the material will be. The TiO2 concentration of ARC-FLASH Photocatalyst reaches 10%, thus it looks like thick milk.

4. Dispersion Technology

|

|||||||||||||||

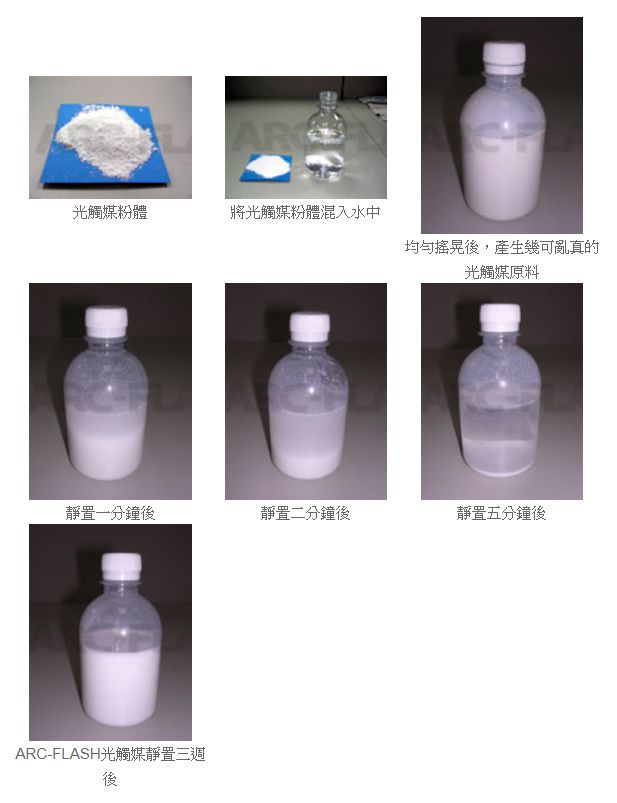

It is very hard to improve TiO2 level of Photocatalyst materials technically, that is why TiO2 concentration of Photocatalyst in current market is

universally less than 1%. Because the density of TiO2 is higher than water, it will easily precipitate and condense in water in a large amount. So as to improve TiO2 level successfully and avoid precipitation, it must depend on a good dispersion technology. Although precipitation is inevitable, with a good dispersion technology it could be dispersed evenly after shaking. ARCFLASH Photocatalyst inside a container will become gelatinous after placed for several days but it will be dispersed easily by shaking. ARC-FLASH Photocatalyst owns a good dispersion technology so that it can raise TiO2 level without affecting the following application.

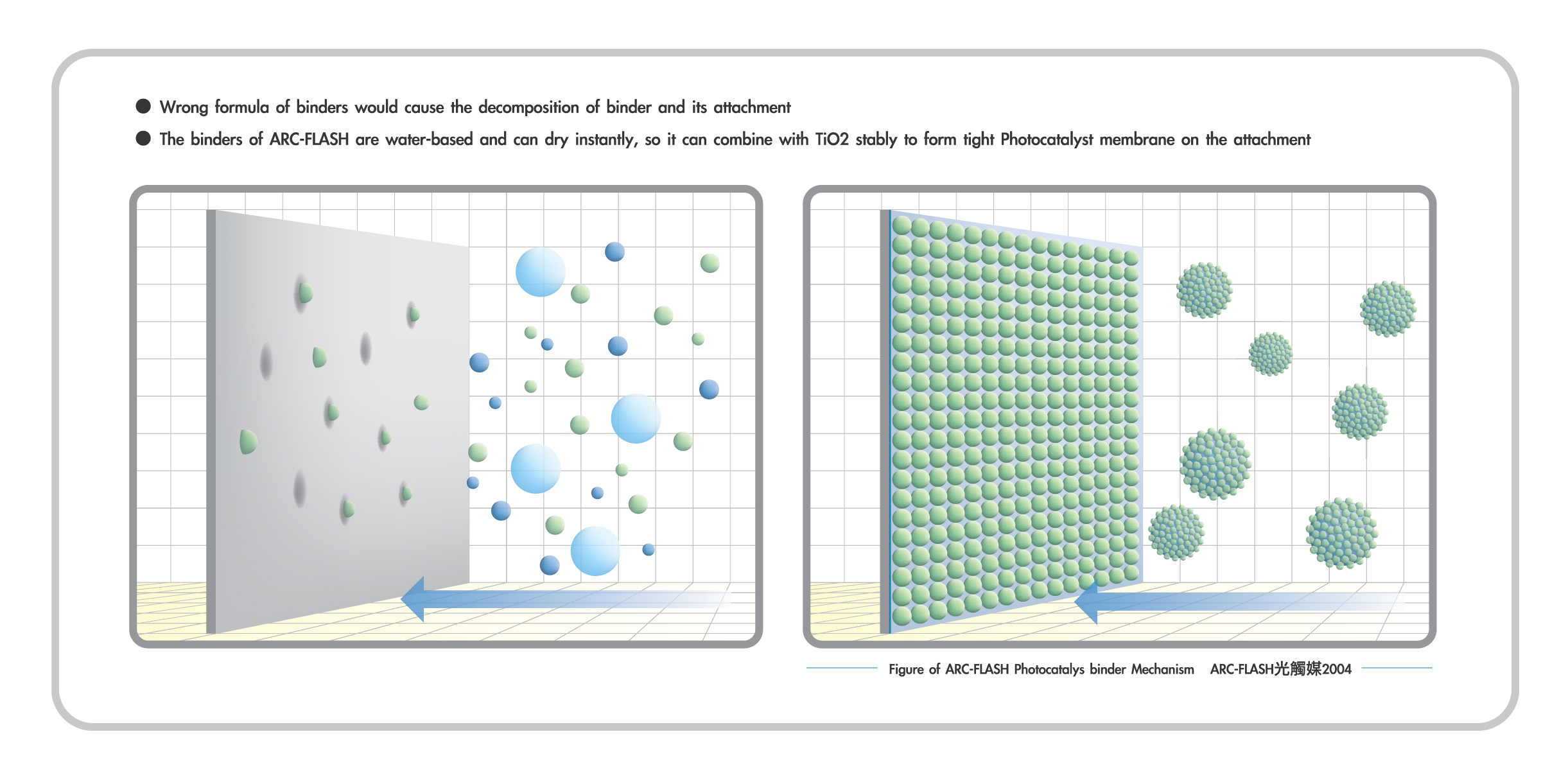

5. Binders

Binders are supposedly used to fix Photocatalyst on the surface of objects but few Photocatalysts applying in the market are using them. Because binders are organic compounds and would be decomposed by Photocatalyst, most manufactures have to give up binders without being able to overcome the obstructions of their applications, which means they cannot fix Photocatalyst by spraying directly. Thanks to the leading technologies, ARC-FLASH Photocatalyst can combine with binders without decomposing them. Through special fixation technologies, it becomes very easy to fix ARC-FLASH on surfaces of any objects by spraying directly.

在2003年SARS期間,有許多媒體報導台灣某大學教授的說法,指出光觸媒若會產生白色的沉澱就有可能是假的光觸媒,這種說法被許多人誤解,以為只要是白色的光觸媒就是假的。其實,光觸媒是以奈米級的二氧化鈦製成,如果含量夠高,一定會是白色的,但若以工業用的大顆粒二氧化鈦來充數,那麼沉殿將會很容易產生,這種光觸媒就是假的。另外,就算用真正的光觸媒粉體直接與水混合,沒有經過光觸媒固定的製程(如分散製程等),依然會產生沉澱現象,也是無法發揮光觸媒功效的。